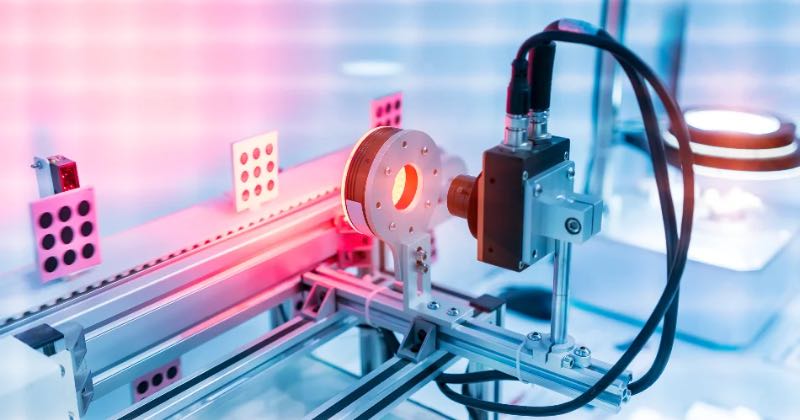

Vision inspection systems are revolutionizing quality control in today’s manufacturing landscape. These advanced technologies are critical for ensuring that products meet stringent standards before reaching the market.

With their unparalleled accuracy and efficiency, vision inspection systems are now indispensable across various industries, from automotive to pharmaceuticals. In this article, we explore how these systems are transforming quality control and why they are essential for modern manufacturing.

Vision Inspection Systems in Automotive Manufacturing

In the automotive industry, precision and consistency are non-negotiable. Vision inspection systems are key to maintaining these standards by using high-resolution cameras and complex algorithms to inspect automotive components with micrometer-level precision.

These systems detect even the smallest imperfections in paintwork, scratches, or misalignments, ensuring that every vehicle meets the industry’s rigorous quality benchmarks. This meticulous inspection process not only enhances vehicle safety but also boosts consumer confidence in the brand.

Enhancing Food Safety with Vision Inspection Systems

Food safety is another area where vision inspection systems are making a significant impact. In the food and beverage industry, these systems automate the inspection process, identifying contaminants or foreign objects in products with high accuracy.

They also ensure proper labeling and packaging integrity, helping manufacturers comply with stringent safety regulations. By incorporating vision inspection systems, food companies can guarantee that only the highest quality products reach consumers, thus safeguarding public health and brand reputation.

Improving Pharmaceutical Quality Control

The pharmaceutical industry demands the highest standards of quality control to protect patient health. Vision inspection systems are vital in this sector, ensuring that pharmaceutical products are free from defects and meet all regulatory requirements.

These systems inspect everything from the sealing and labeling of medication to the detection of contaminants, helping pharmaceutical companies maintain compliance and deliver safe, effective products. The adoption of vision inspection systems in pharmaceutical manufacturing not only improves product safety but also enhances production efficiency.

Vision Inspection Systems in Electronics Manufacturing

In the electronics industry, precision is critical for the performance and reliability of products. Vision inspection systems enable manufacturers to inspect circuit boards, components, and assemblies with extraordinary detail.

They can identify defects such as soldering errors, missing components, or misalignments, ensuring that electronic products are of the highest quality. By integrating vision inspection systems into their production lines, electronics manufacturers can reduce defects, enhance product reliability, and accelerate time to market.

Driving Efficiency in the Packaging Industry

The packaging industry benefits greatly from the automation and precision offered by vision inspection systems. These systems inspect packaging materials and finished products for flaws, verify label accuracy, and ensure proper product placement—all at high speed.

By minimizing human error and reducing the risk of defects, vision inspection systems streamline packaging processes, improve product quality, and enhance operational efficiency. This technology is essential for packaging companies looking to maintain competitiveness in a fast-paced market.

Conclusion: The Future of Quality Control

Vision inspection systems are more than just tools—they are catalysts for excellence in quality control across diverse industries. By leveraging advanced technology, these systems ensure that manufacturers can uphold the highest standards, reduce defects, and deliver safe, reliable products to consumers.

As these systems continue to evolve, they will undoubtedly play an even more critical role in shaping the future of quality control, setting new benchmarks for efficiency, accuracy, and reliability in manufacturing processes.